Introduction: Beyond the Clipboard

For decades, work instructions have lived on paper binders, laminated sheets, and spreadsheets pinned beside the line. They were necessary — but also static, outdated, and often ignored. Today, Digital Work Instructions (DWIs) are changing the game.

But here’s the truth: going digital is not about “replacing paper.” It’s about unlocking measurable ROI across productivity, quality, training, and compliance. Companies that implement DWIs correctly are seeing double-digit efficiency gains and a step change in operational discipline.

Why Traditional Instructions Fall Short

Even in world-class plants, paper-based or static PDF instructions cause friction:

- Outdated versions floating around the floor, causing errors.

- Long ramp-up times for new operators who can’t absorb dense instructions.

- No real-time feedback when defects or delays occur.

- Audits and compliance slowed by manual signatures and scattered documents.

In Lean terms, paper instructions are a form of waste — they add motion, waiting, and defects to the process.

The True ROI of Digital Work Instructions

1. Productivity: Faster, Smoother Execution

By guiding operators step-by-step with visual, interactive instructions, DWIs eliminate guesswork.

- Studies show 15–20% productivity improvement within the first year of deployment.

- Workers spend less time stopping to ask questions or searching for the “right binder.”

- Integrated timers and checklists keep the flow moving without constant supervision.

Case Example: A mid-size electronics assembler introduced DWIs on critical assembly stations. Operator cycle times dropped by 18% while first-pass yield improved by 12%.

2. Quality: Reducing Defects at the Source

Errors don’t just waste material — they damage customer trust. DWIs help prevent them.

- Built-in verification steps (e.g., photo confirmation, barcode scans).

- Visual cues (photos, videos, diagrams) instead of ambiguous text.

- Automatic version control ensures only the latest revision is live.

ROI impact: Plants report 30–40% fewer rework incidents after going digital. That translates directly to material savings and warranty cost reduction.

3. Training: Onboarding in Days, Not Weeks

Workforce turnover is one of the biggest hidden costs in operations. Traditional training takes weeks, with shadowing and trial-and-error.

DWIs act as a built-in trainer:

- Interactive, step-by-step guides cut onboarding time by up to 70%.

- New hires reach full productivity faster — critical in tight labor markets.

- Knowledge capture ensures tribal expertise is embedded, not lost.

4. Compliance: Easier Audits, Stronger Traceability

Industries like aerospace, automotive, and medical devices live under strict compliance. DWIs create a digital audit trail automatically.

- Electronic sign-offs by operator, shift, and supervisor.

- Real-time traceability of every unit, step, and operator involved.

- Audit prep drops from days of paper gathering to a click-through dashboard.

ROI impact: Reduced compliance risk and avoided fines — harder to quantify, but very real.

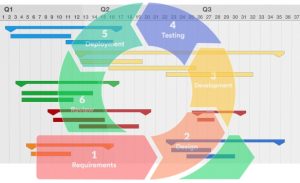

5. Integration: PLM, ERP, and MES Synergy

The best DWIs aren’t standalone. They integrate with PLM and ERP systems, linking design to execution:

- PLM → pushes new revisions seamlessly to the floor.

- ERP/MES → receives completion data, scrap counts, and productivity metrics.

- Managers gain live visibility: which line, product, or operator is performing to standard.

This closes the loop between engineering, operations, and quality.

The Investment and Payback

A common hesitation: “Another software license, another IT project.”

Here’s the reality:

- DWI platforms are lightweight compared to full MES.

- Deployment can start on one line or one product family and scale.

- Typical payback: 6–12 months, driven by faster cycle times, lower rework, and reduced training costs.

Implementation Pitfalls (and How to Avoid Them)

- Over-complicating content

Don’t just upload PDFs. Break instructions into bite-sized, visual steps. - Lack of operator involvement

Engage operators in design — they know where confusion lives. - No champion

Assign a cross-functional lead (Ops + Quality + IT) to drive adoption. - Failure to integrate

Isolated tools create silos. Plan for PLM/ERP links early.

Action Checklist: Is Your Plant Ready?

- High defect or rework costs?

- Long new-hire training cycles?

- Struggling to keep instructions current?

- Painful audits or traceability gaps?

If you checked “yes” on two or more, the ROI case for DWIs is already strong.

Conclusion: Beyond Paper, Toward Performance

Digital Work Instructions are not about screens replacing clipboards. They are about unlocking the next level of operational performance.

- 20% productivity gains

- 30–40% defect reduction

- 70% faster onboarding

- Simpler compliance

The ROI is clear. But more importantly, DWIs represent a cultural shift — one where information flows seamlessly, errors are prevented at the source, and operators are empowered to perform at their best.

At Genexxia, we help companies integrate DWIs with PLM, ERP, and Lean initiatives for measurable results. Ready to explore your ROI? Contact us to book a 30-minute operations review.